Kiczan Precision Manufacturing

For the Products You Can Depend On

Over 40 years, Kiczan Manufacturing has grown to serve some of the largest companies in the USA, as well as many local and specialty manufacturing concerns. Our work ranges from large production runs fulfilled on-time and on-budget to custom parts manufactured to the highest tolerances for specialty application. A full-service job shop, we take your order from milling and grinding through to painting or powder coating and assembly.

Would you like to learn more? Contact Us today or give us a call at 412-678-0980.

Machining

Our multi-station machine shop features a wide range of computer-controlled equipment, affording complete flexibility for precision machining of both standard and custom parts, regardless of complexity or quantity. Available machining operations include:- Milling

- Drilling

- Slotting

- Tapping

- Boring

- Turning

- Sawing

- Grinding

Metals Joining

Machining and fabricating operations are complemented by our modern metals joining shop, which includes complete facilities for welding, grinding and assembly of finished pieces. In addition, the shop is fully-equipped to provide all essential prep-work and finishing, including:- Welding

- Resistance Brazing

- Torch Brazing

- Soldering

- Spot Welding

- Deburring

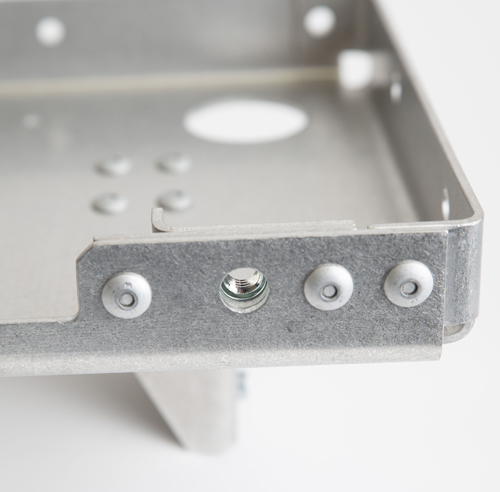

Fabricating

Kiczan Manufacturing is a precision sheet metal fabricator specializing in small to medium volume requirements. Our sheet metal products consist of panels, chassis, brackets, bus bars and more, in materials ranging from:- Aluminum

- Steel

- Stainless Steel

- Copper

- Brass

- Architectural Metals

Finishing

To complete the process , we offer a wide range of finishes, including:- Painting

- Powder Coating

- Brush Finishes

- Tumbling

- Time Saving

- Polishing